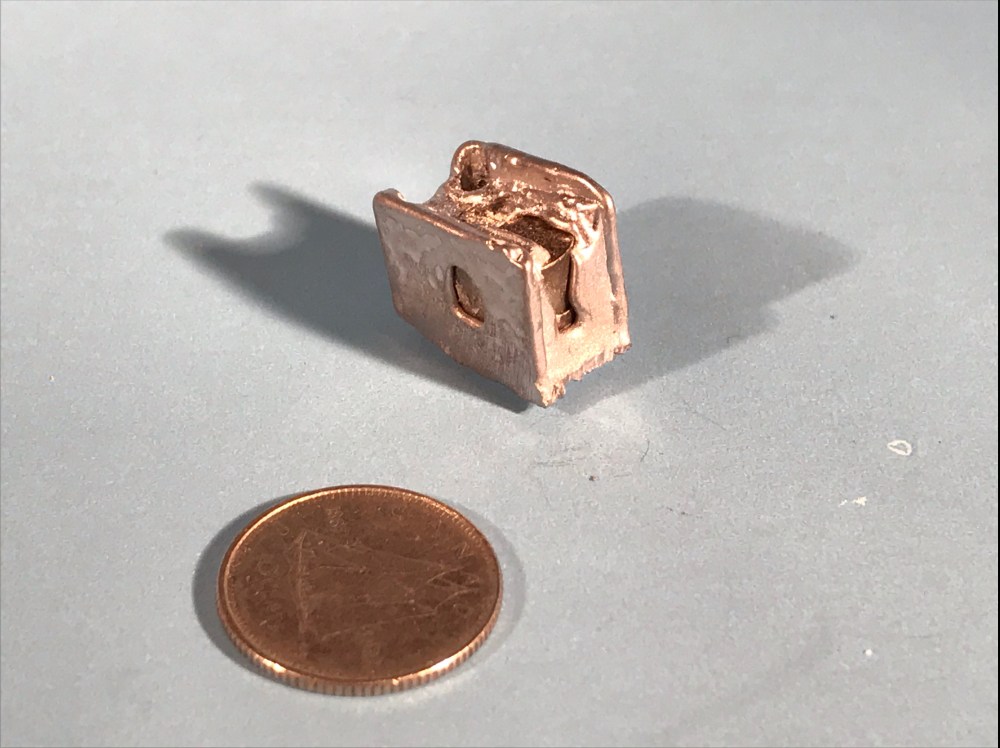

As with most other parts of 622, I wound up making the firebox weight twice. The first time was pretty bad due to an incomplete burnout of the wax or poor flow of the lead. The second one turned out passably well, and only took one attempt to carve the wax!

As you can see, while the second attempt did fill the void, the surface tension of molten lead is pretty high, and it didn’t want to completely enclose the tungsten weights. I don’t know if the lost lead is enough to outweigh the benefit of the tungsten.

With the new weight in place, I checked how the balance of the locomotive is shaping up. Prototype eight-wheelers typically have equal weight on each driver and on the engine truck. This means the center of gravity should be 2/3 of the way between the engine truck and the equalizing pivot. With the new weight, 622 balances at about 1/2 way. To get that other sixth, I need to cram quite a bit of tungsten into the cab.

The engineering here is pretty complex.

Calling this engineering is a bit of a stretch, but thank-you Richard.

Incidentally, I epoxied the weight in place today.

Why tungsten, and would you fit hind the boiler backhead?

Happy Holidays, Richard! Tungsten is 74% denser than lead. You may not have to worry so much about the weight of your giant O-scale engines, but in the junior scale, I need to pack in as much as I can.

There may be room for some behind the backhead, but there are a bunch of wires that need to thread through that space, and so I’m not ready to fill it up just yet!

Your right, weight generally isn’t a problem for me. My locomotives are heavy enough to survive most interactions with cats. Spelling is. I wish I could correct mine after I post which is usually when I see my mistakes.

Thank goodness there are no cats here! Proto:87 flanges wouldn’t survive a casual flick!