The challenge with the 4-4-0 wheel arrangement is to move the weight distribution to the rear of the engine, toward the drivers. As I found previously, I need to squeeze a lot of weight into the cab.

This weight takes the form of tungsten, 74% denser than lead and conveniently available from Woodland Scenics’ Pinecar division. So, as I was waiting on other parts, I started grinding down heavy duty cut-off discs. Seriously, tungsten is like adamantine kryptonite for cut-off discs. The operation slowly grows a slot in the metal while generating a cataclysmic cloud of dust that is probably best kept outside on the other side of a mask if you can find one not strapped to a COVID-19-frantic public transit user.

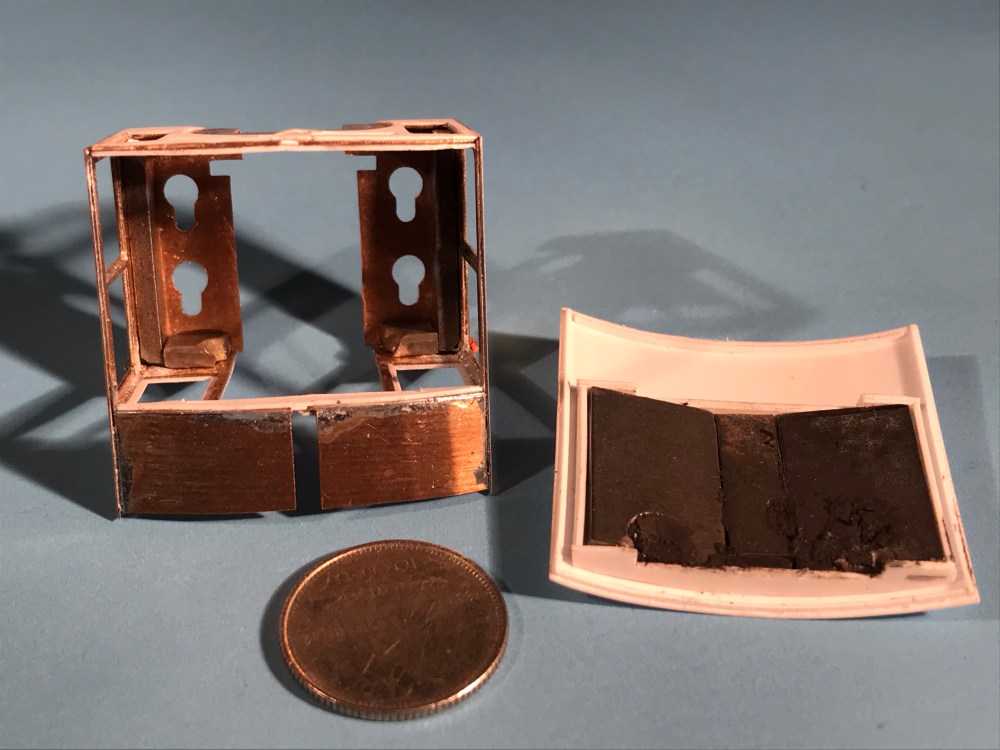

The Pinecar weights come with screw holes that would be handy if I had room for screws. I don’t, and so the weights are glued in place, obviating the holes. To fill them in, I reactivated some Pinecar tungsten putty by heating it in hot water and then mixing it with Vaseline (as heroically described in this post).

So far, I’ve squeezed 1.2 of the 2 ounces I reckon I need into the cab. There may be room for more around the wheel covers and the rear end of the firebox, but I think I will wait until I see the backhead before releasing more dust.

Is it possible to bring some of the weight from the tender to bear on the rear of the loco? Build the tender as a sort of semi trailer, so that the weight from the front half bears on the drawbar and the front bogie is sprung just enough to go along for the ride.

Best wishes

Eric

Thanks for the suggestion, Eric. I’ve come across this idea before. Was it perhaps one of Mike Sharman’s manoeuvres? In any case, it seems to me that it trades one problem for another. Gain adhesion, but derail the front tender truck.

Rene

It Is certainly a device that was used by Mike Sharman – particularly for Cramptons and similarly exotic early locos. It needs a bit of trial and error to get enough weight to keep the leading bogie in place, but the majority of it bearing on the rear of the loco. For my money, it would be a lot easier than trying to carve shapes in chunks of tungsten!

Best wishes

Eric

Fair enough!

See comments by Barry Luck on his locos which are regularly exhibited on layouts of Pulborough and Plumpton Green. His 4-4-0 is described in detail at

http://www.lbscrmodels.co.uk/norfolk.html

Best wishes

Eric

Tungsten putty (or powder) is much less dense than 100% pure tungsten. Lead is more dense than tungsten putty. The putty is 10g/cm3, lead is 11.3g/cm3. Pure tungsten is 19.3g/cm3. Not that that it matters in this case just passing along info. You can get tungsten alloy that is less pure and be able to machine it. Also there are tungsten welding rods. These can be scored with a diamond bit and then snapped to size.

Thanks Chris. Yes, I’m regarding the tungsten putty as just slightly better than the air that previously filled the holes.

Thanks also for confirming that tungsten welding rods are actually tungsten and not some tungsten alloy. I shall have to look into the machinable tungsten alloy…