When I mated the boiler and the etched frame for the first time, they produced a dead short. Somehow, I had reversed the framigami pattern so the left side ended up on the top rather than on the bottom as planned. Fortunately I noticed before bringing any destructive electrons to the party.

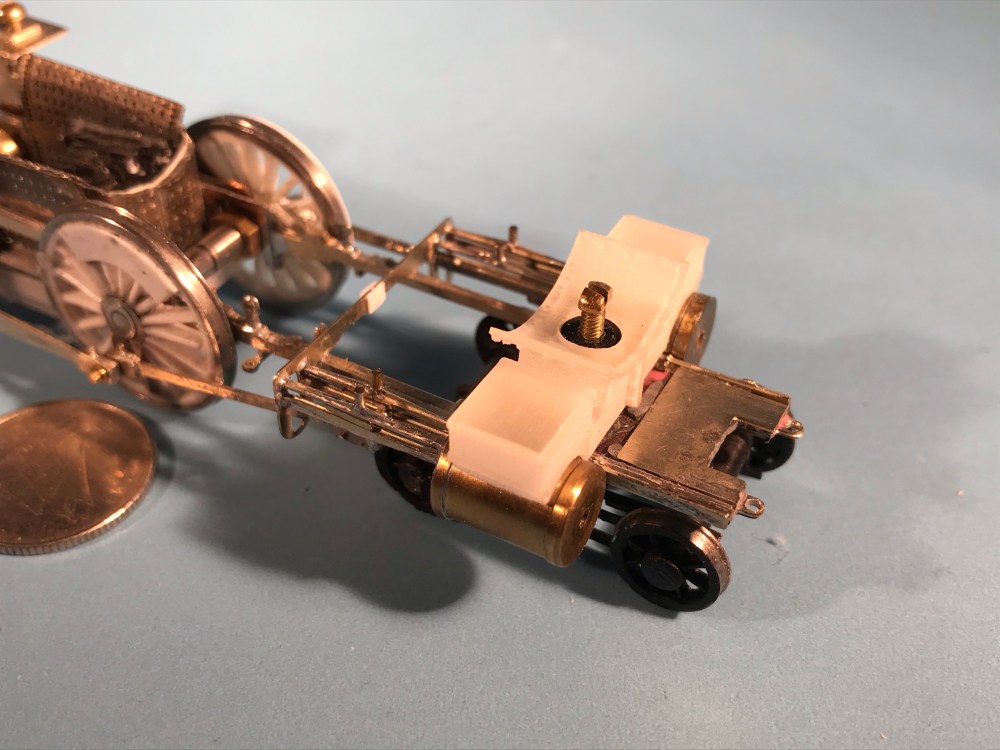

The situation remained unresolved, although I had a plan in mind for many months. This week it could wait no longer, but when I got serious about the plan I realized I could simplify it. Instead of a sheath holding two halves of the tapped brass tube in isolation from one another, I simply made an acetal tube that fit over half the brass tube. I drilled this and tapped it for the boiler screw.

The 3D-printed boiler saddle wanted a bigger hole to fit over the new acetal tube. Drilling this took longer than you can imagine because I had visions of the part disintegrating as I drilled. I took it very slowly, and wiped my brow when I was done.

I was so surprised by how well the boiler, cylinders and saddle all fit together, I had to pose 622 in front of the roundhouse for a quick snap. Hopefully nobody decides to drive her away as she’s off the track.

The acetal muff insulates the boiler from the top half of the frame. The T-shaped screw slides into a slot in the boiler and holds the boiler against the saddle.

The saddle slips over the muff and – amazingly – over the cylinders!