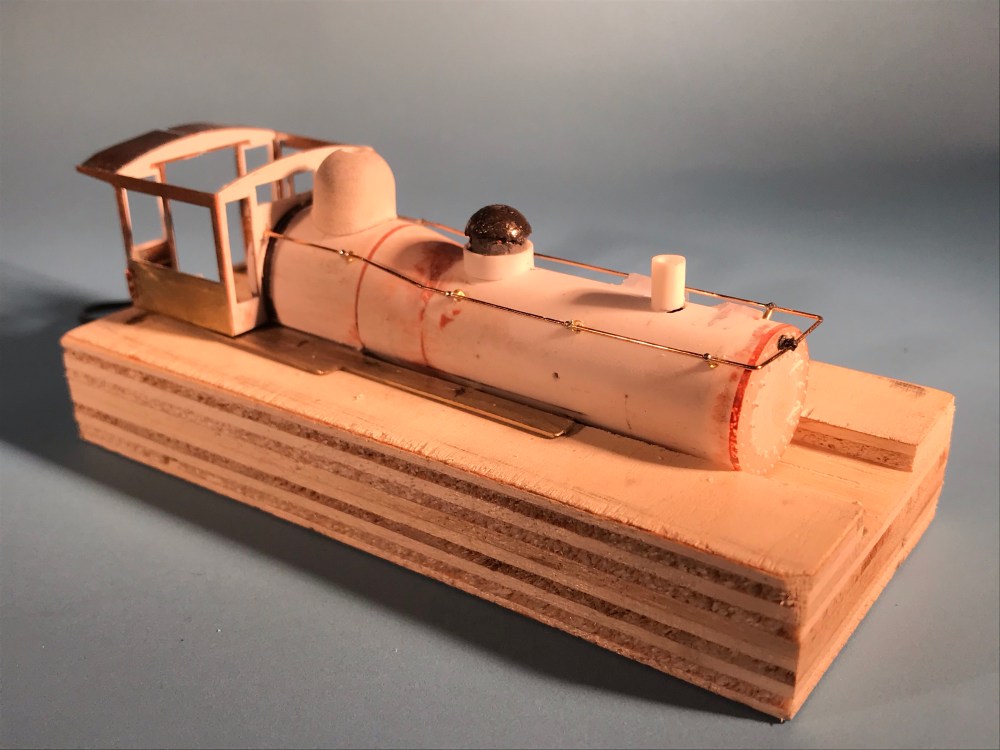

All I can say is at least it is straight across the front. Most North American steamers that I’m familiar with keep their handrails chastely separate on either side of the boiler. If there was a handrail across the front of the smoke box, it was another piece, disjoint from the side rails. Sadly, 622 and her sisters had a stylish wrap-around handrail that joined both sides together. At least it wasn’t one of those fancy GWR engines with the wraparound handrail that also follows the shape of the boiler.

Fortunately, there was a stanchion in the middle of the smokebox. This enabled me to make two separate handrails and join them inside the stanchion, reducing the number of bends that had to be in exactly the right places.

Even so, getting all the stanchions sort of lined up, and the straight bit of wire straight and level took hours of fiddling. The trick seemed to be to hold one end with my asbestos fingers, while the smokebox stanchion held the other end. Then I lined each stanchion up to a surface gauge and quickly zapped it with a little solder.

The stanchions themselves are only as deep as the plastic boiler lagging. So, they need to be held up by each other to avoid sagging. I’ve made them, along with all the other boiler details as separate subassemblies to aid in painting later.