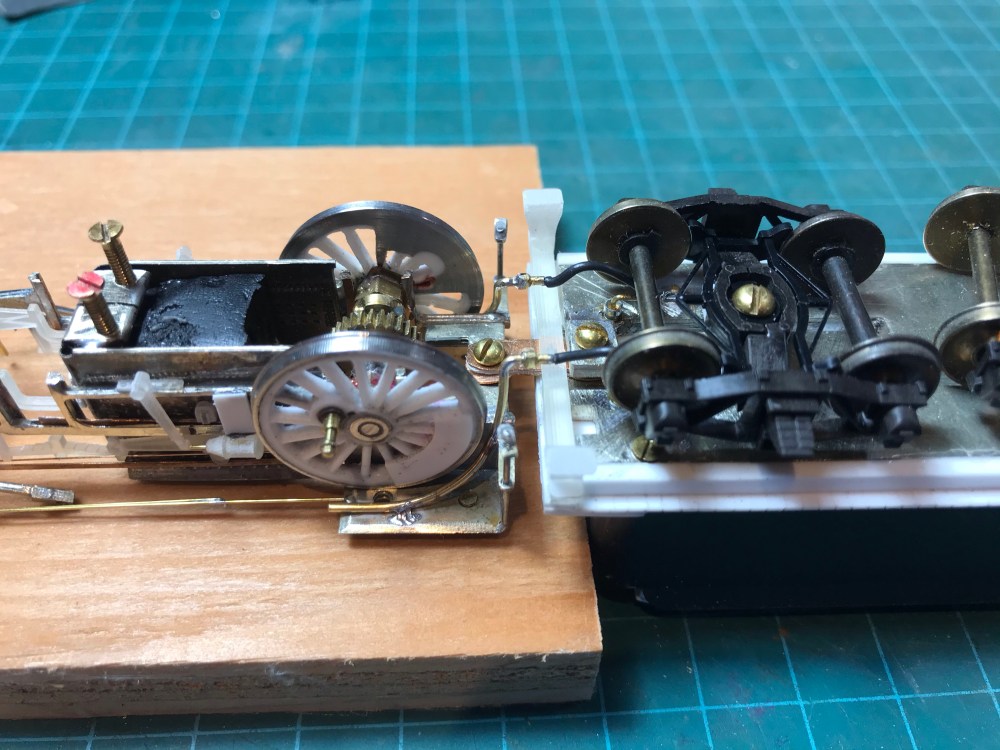

It may look like #622 is all but finished, but I just put together a to-do list with 28 items on it before the engine is ready for paint. Many of those items need to be fabricated, which means each will take at least an evening. Here are the first three from the list.

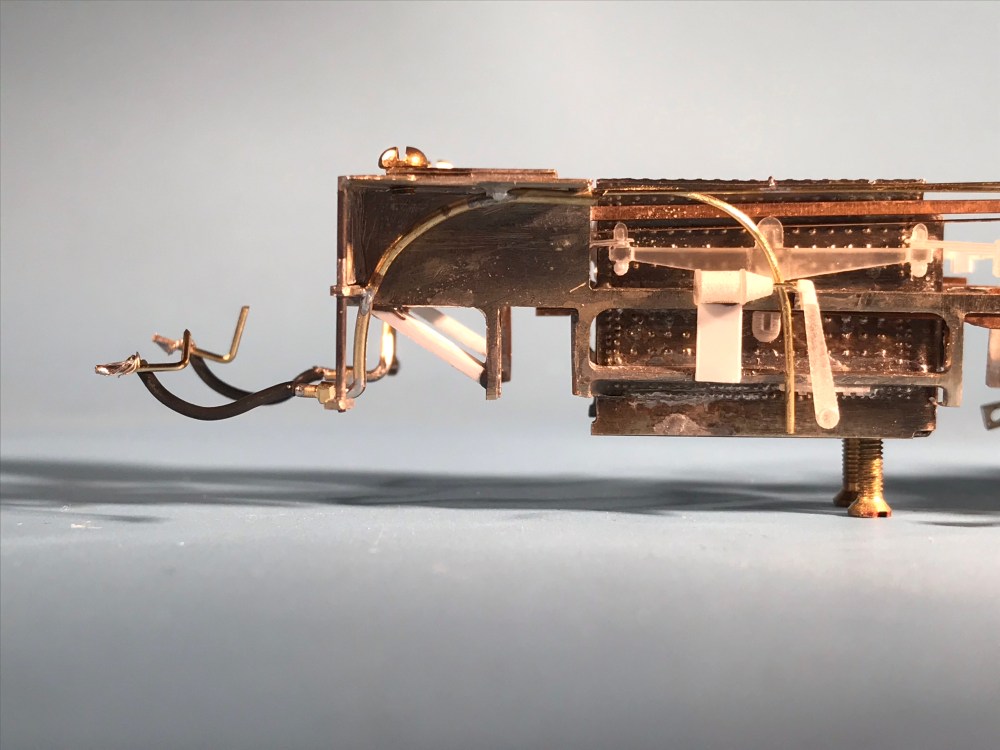

The feedwater hoses carry electricity between tender and locomotive; I think in a future version, I will figure out an alternate use for this connection as the coupling does the same. The feedwater pipes and injector overflow pipes both need to thread their way around the rear wheel in wild contortions. Sadly, I didn’t help myself by including holes or other supports for these pipes: they’re simply clamped in place and soldered.

With the soldering complete at the rear of the engine, I could finally finish the frame, adding those diagonal elements in styrene. I made a simple template from the Onshape model to get the end angles correct.