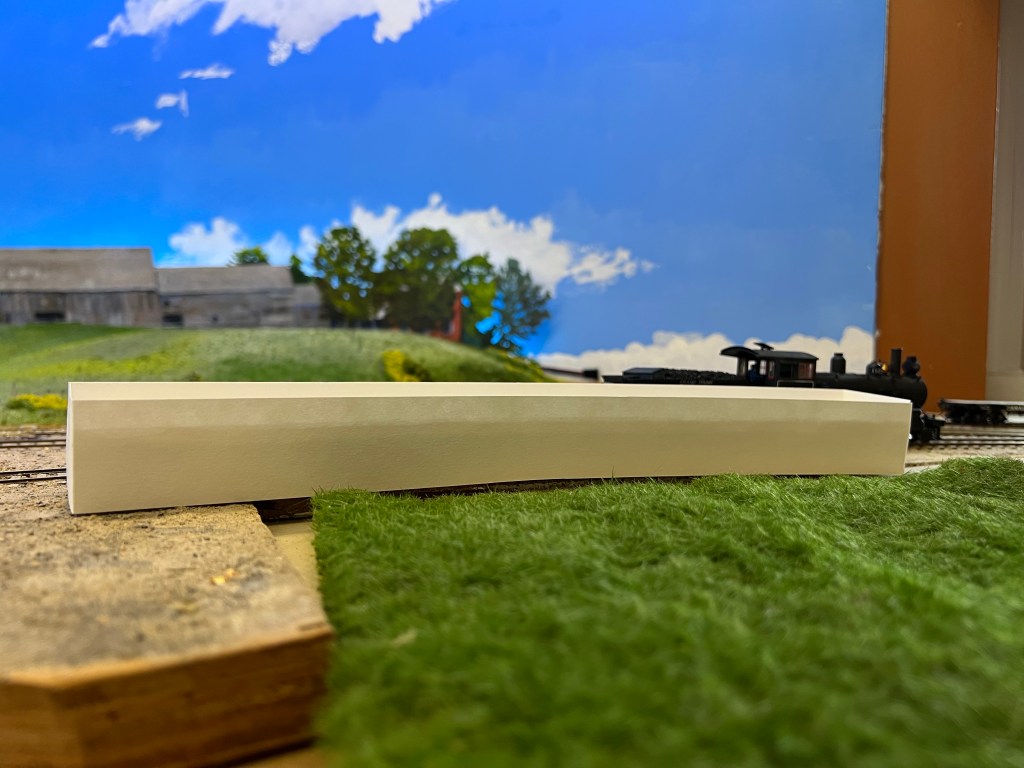

My last post about the coaling station prompted me to re-examine my sources. I found a second mention in the 1908 Bridges and Buildings book, which gives 92’x12’ as the actual size of the coal dock.

There were half a dozen other coal docks on the Canada Atlantic, and they were all a more modest size. However, most of those appear to have been placed for emergency use or in smaller branch line terminals. By contrast, Number 51 left Pembroke each morning at 7:45 and Number 45 was at 8:40. Both engines would have had to fuel at about the same time. So the railway must have built the dock to suit. I wonder if this was designed from the start, or if they enlarged the dock later.

On my version of Pembroke, a 92’ dock takes almost the whole engine lead, leaving little room for a section shed and a couple of old box cars that were somewhere in the area. In the 50s, there was a bunk house and section shed on the west (near) side of the tracks; buildings, even when replaced tend not to move far, so at least the section shed should share some of the length with the coal dock. The box cars could be on the far side of the track, though.

Would crews be able to safely dump ashes in front of this wooden structure, and rake them out on the opposite side of the track? Watching YouTube videos of similar operations, I think they could, though they wouldn’t appreciate the structure preventing access to one side of the ash pan.

Clearly the basement requires some compromise here. Either I have to accept that the whole lead will be more crowded than it probably was in real life, or the coal dock needs to be shorter than it was. Either way, I can not escape the realization that the coal dock needs to be long enough to fuel two engines simultaneously.

At the risk of making a silly suggestion, could you size it so the locomotives could fuel back to back, and the turn one around when it’s ready?

Or am I missing the point?

I don’t think you’re missing the point at all, Richard. I did think about fueling back-to-back, but I feel that would be an unusual operating procedure. Getting on and balancing the turntable takes time, and you wouldn’t want to have to take that time twice!

Hi Rene,

You clearly don’t have room to model the prototype dock and ancillary structures “to scale” so you need to ask yourself “What story am I trying to tell?”

If the ‘story’ is slavish accuracy to the prototype model the dock full scale and let all that other stuff fall off the edge of the benchwork, as it were. You may want to consider if the full scale prototype dock “looks” too large for the modeled scene.

If you’re trying to tell the story of the railroad in its setting then model a compressed dock and include all those other elements that give the finished model ambience and “texture.”

Personally, if it were me, I’d pick one of those 6 other (shorter) docks from another town on the line and use that.

There’s no right or wrong here, and no matter what you choose I’m sure the result will look great!

Marty

Thanks Marty. This is super advice!

Rene, I’m curious as to the procedure they would have used on your prototype, do you have information on it? At many terminals, engines were serviced on arrival. Readying for departure they would only need to be topped up. This could be a way to avoid an imposing coaling dock

Hi Brian, I confess, I don’t know. The CA rule book says, “[enginemen] must also have their engines in good working order, supplied with fuel and water and ready to attach to train at least thirty minutes before leaving time,” and also that the engineman must keep charge of their train to and from the roundhouse. The GTR motive power rule book states that they should deliver their locomotive at the coal chutes upon arrival. So perhaps you are right, but perhaps it doesn’t matter as the two crews tied up about an hour after one another too.

Would engines be fueled before their journey or at the end and before they were bedded down for the night? I see your notes (to Brian) above and wonder if you could bookend a session alternating fueling on arrival or on departure.

Echoing Marty’s comment is this also a place where we can embrace some theatre in the operating session? Even if all engines are only fueled before departure do you need to model that for both or can one engine be going through the full process while the other loops around it and pretend implies it happened? Modelling between what we need to see for the presentation style of the session.

-Chris

Loco’s were often coaled after inspection after arriving at the shop track. Thus only topping-up would be required at most. Fires were usually banked to keep a head of steam available during a layover between trains. There’s plenty of time to fuel a loco on arrival, and often little time to fuel it before departure.