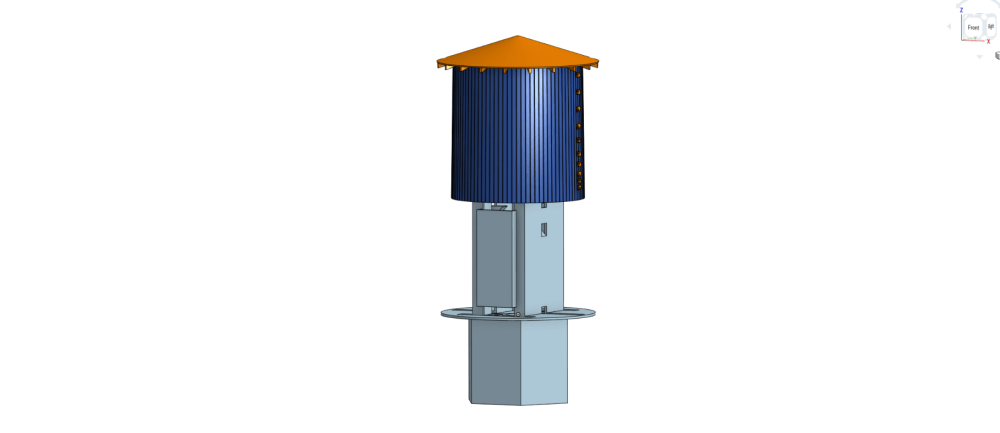

The water tank is beginning to take shape, at least in a virtual world. This will be a hybrid model – a mixture of 3D-printed and traditional parts, with perhaps a few more 3D-printed parts than are strictly necessary.

The base, which interlocks with the mechanism beneath the baseboard, and a few test hoop connectors are printing as I write. If all goes well, the tank and roof will go on the printer tomorrow.

I plan to use fishing line for the hoops, themselves, and the tests will show whether I’ll be able to thread the line through the connectors or not. This will be ideal as there is an air gap between the hoop and the first plank on either side of the connector. If I can thread them, then the tank has holes to locate each of the connectors. That should help to keep the hoops straight. If the connectors cannot be threaded onto fishing line, then I will print the hoops.

The connectors, modelled after those on the Wakefield tank, admit a jolly amount of variation. Some of them have a cover that hides the skeleton, while others do not. About half of them are arranged so the right side passes over the left, and the others are vice versa. It is details like this that I find make prototype modelling so rewarding – if I can pull it off!

After further reading about water tanks, I’ve decided to use a float on the side of the tank to indicate the water level. It seems that the ball on the finial approach was more common in places where the state of the tank needed to be communicated at a distance. What’s more, I found the tall finial was out of proportion with the tank.