After redesigning the trucks with inside brakes, I printed a test copy. It worked fine the first time, but I noticed the axles could be a little tighter in the bearings. This should assist with getting the ride height of the cars correct. A pair of .005″ shims inserted after the wheels seems to keep the axle ends near the bearing ends so the trucks don’t sink perceptibly when loaded. Rather than modifying the design, I’m going to keep this post-assembly adjustment to allow for differences in axle length or printing.

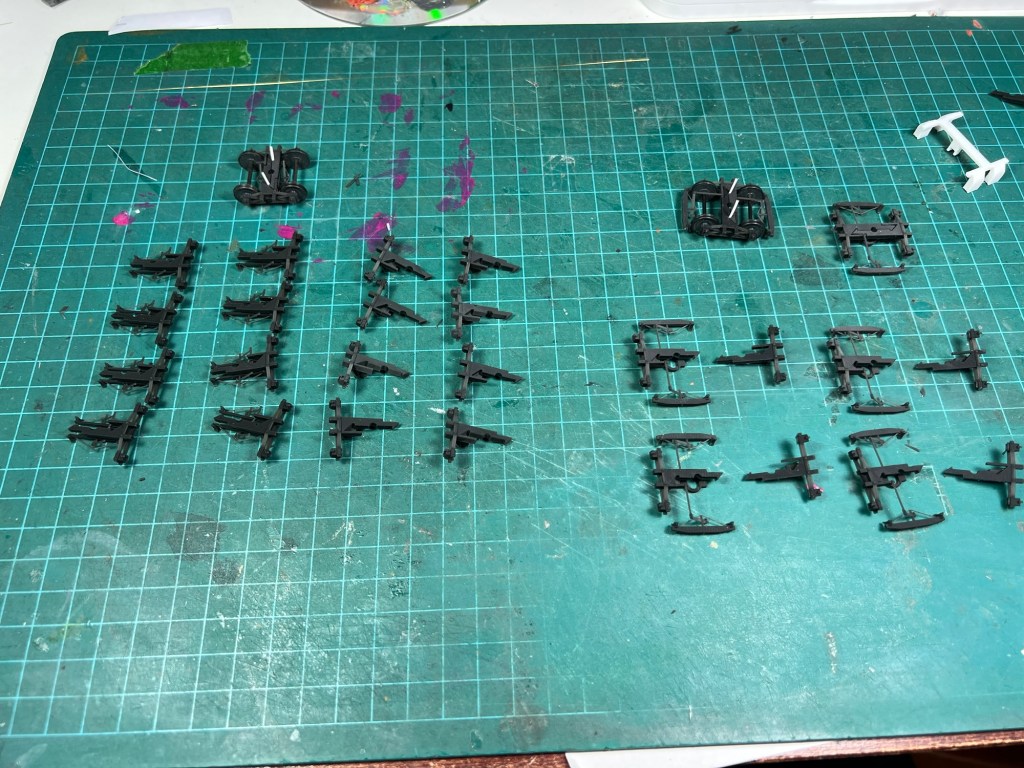

I then proceeded to print a small mound of parts. There was only one failure: a bottom chord of one truck didn’t survive separation from the supports. Fortunately, I could just use the test truck, so I still had eight trucks.

I then assembled the trucks without wheels, and washed them, ready for painting. I was started to ball up tiny pieces of poster putty, but got bored after masking a couple of journals. I could see that masking all 48 journals was not going to be a rewarding use of my time. So I designed a contraption that will hold onto the truck while masking the journals all in one go. I’ll print this on the FDM printer, and if it works, painting will be a doddle.