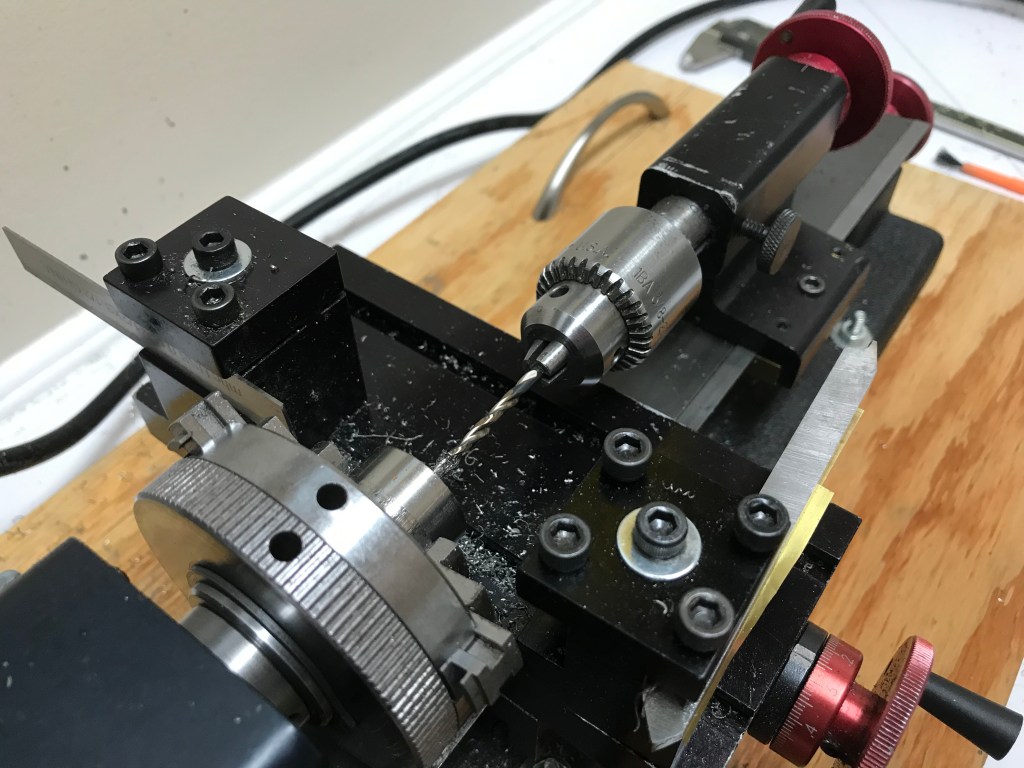

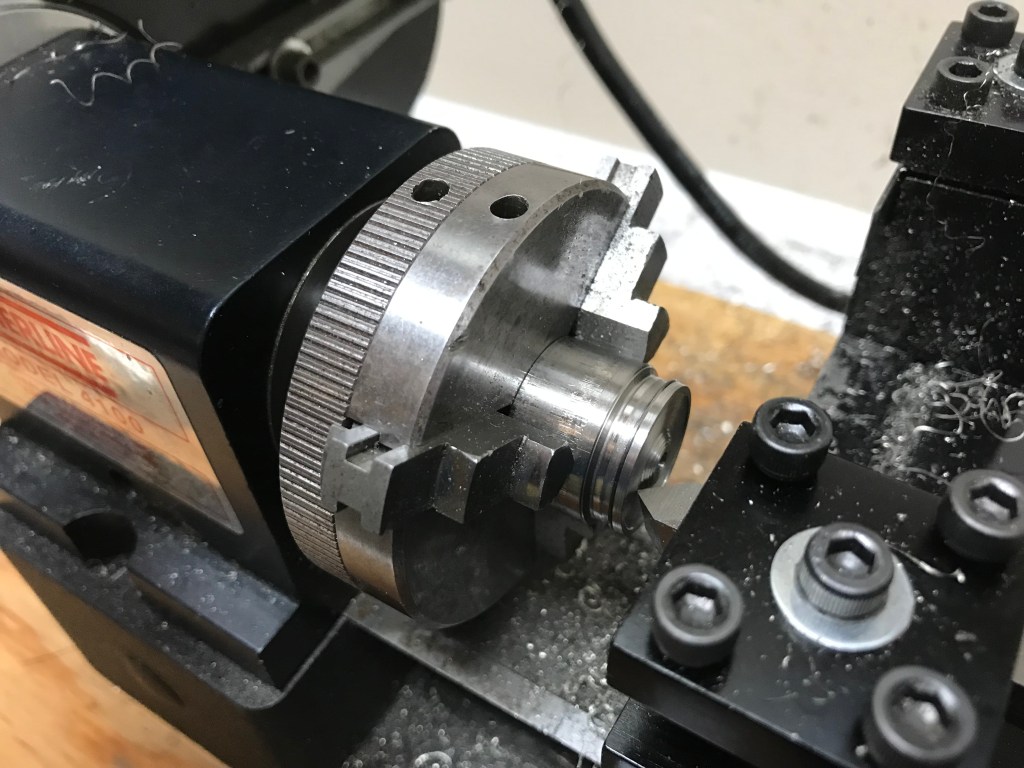

It has taken a week longer than I wanted to turn the drivers for 622. These are made from 303 stainless steel, which I’m fairly convinced is almost the limit for my little Sherline lathe. Certainly, all tools need to be sharp, and shallow cuts are de rigeur. Along the way, I have seen a steady improvement in the quality of the output. From the first sample, which was frankly not very good, to the last ones, which are quite acceptable.

I wound up cutting seven, and will keep the best four. One is so bad I will only use it for experimentation! The first couple exhibit significant chatter on the tyre.

Along the way, I learned that I can get two wheels out of a one-inch piece of stock, and that anything longer is not a good idea because you want to part this hard material close to the chuck. I also figured out the best sequence of steps to balance speed with accuracy. Here, then, are the instructions for when I need to cut more drivers:

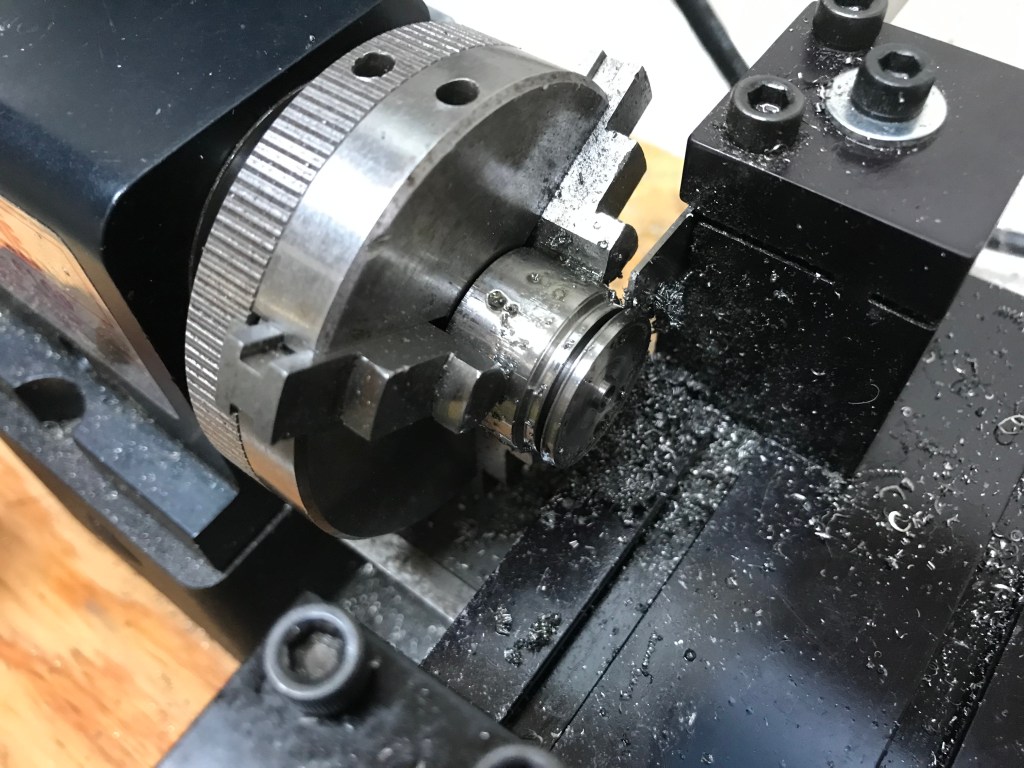

Face both sides of the stock.

Run the lathe at about 3/5 of the dial speed.

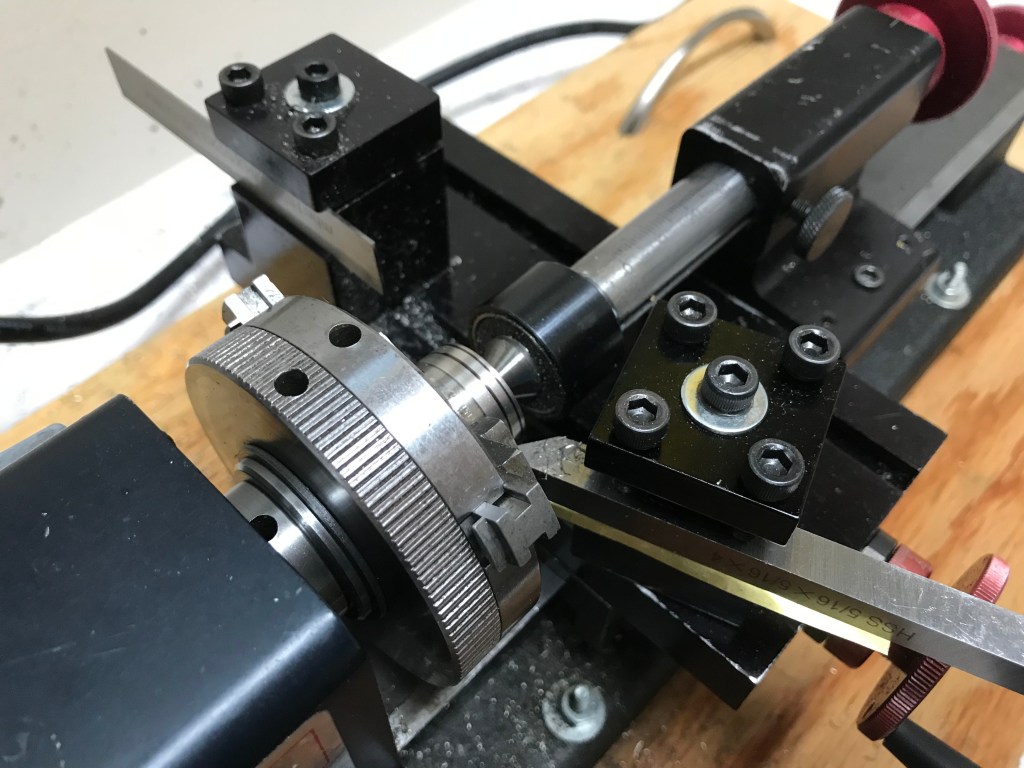

Use the squared face to set the sharp cutoff tool.

Centre-drill and then drill a 3mm hole 4mm deep.

Turn a 6mm cylinder about .2 mm larger than the flange diameter.

Turn a 3mm slot as deep as the V-tool will allow.

Use the V-tool to cut a relief on the face of the wheel.

Use a special tool to roughly straighten the back of the wheel blank.

Finish turning the wheel to about .02 mm larger than the flange diameter.

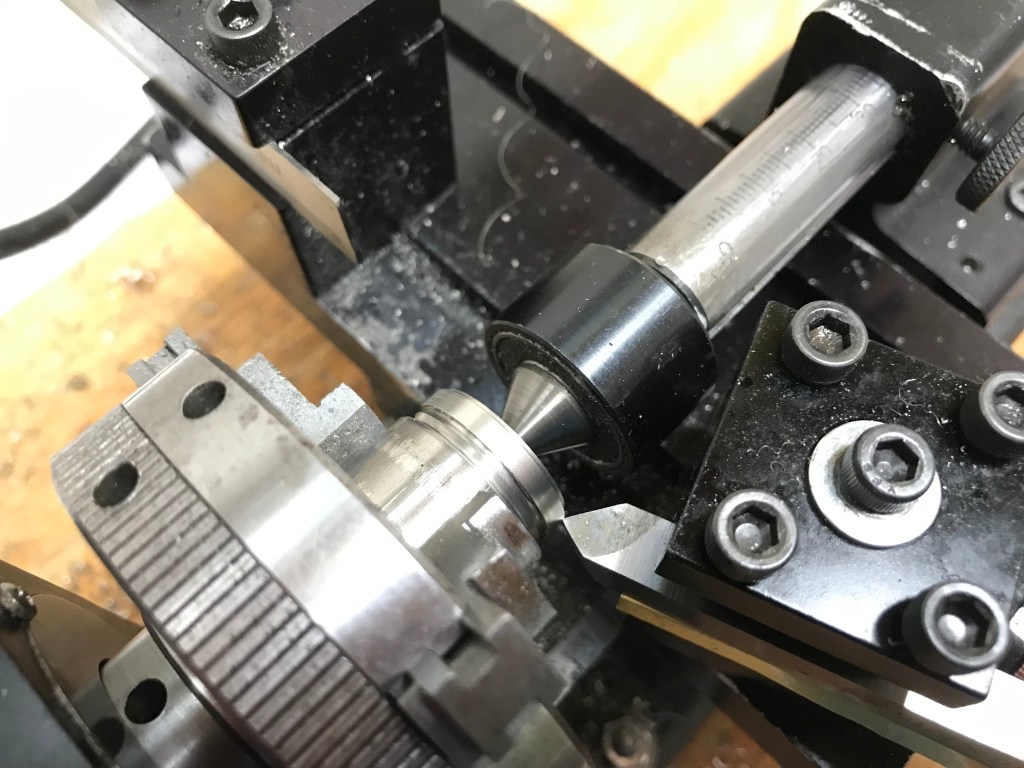

Form the tread with a sharp form tool running at about 1/4 speed.

Knock any chatter off by slowing the speed down.

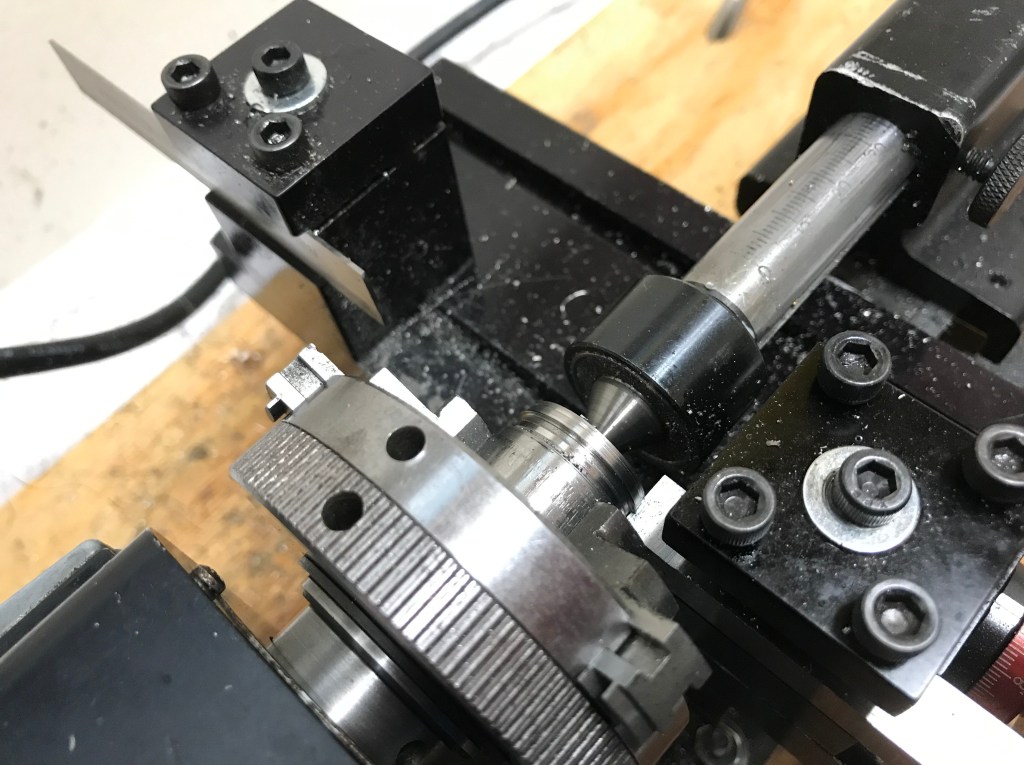

Face the wheel to the depth of the boss (2.44 mm)

Face the wheel down to the tyre width.

Then cut a dish down to the spoke surface.

Turn the inside of the tyre down to the spoke surface.

Turn the boss down to the surface of the spokes.

Part off the wheel using lots of oil. About 1/3 speed.

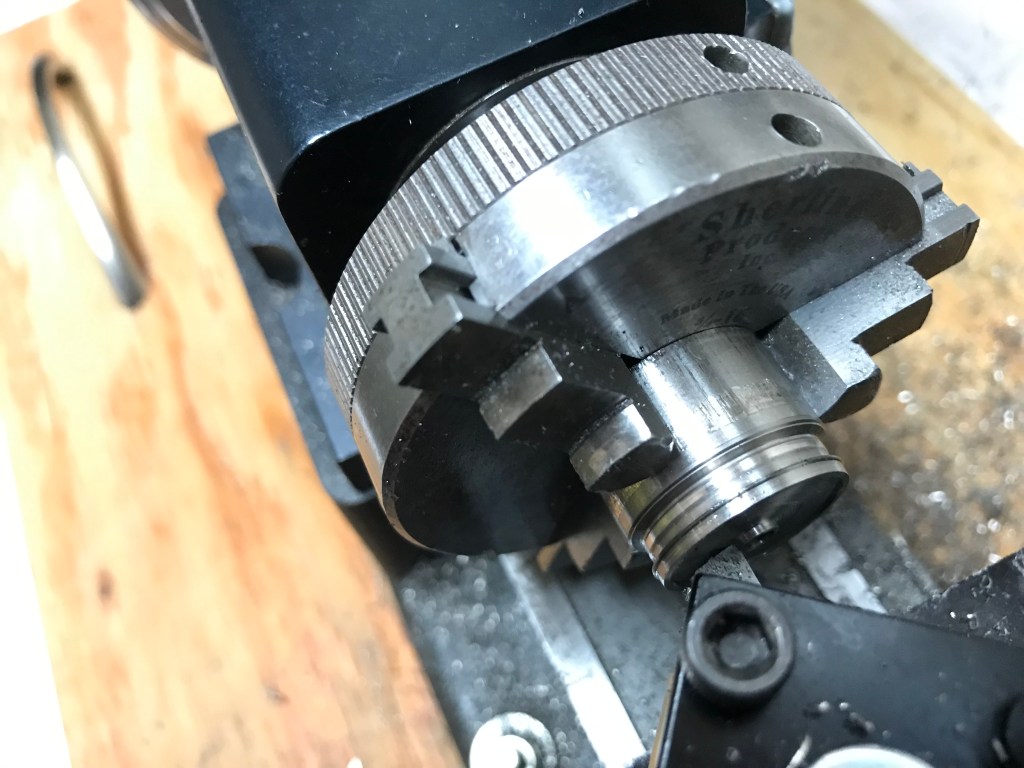

Notice the stock has started to pull away from the chuck. Why?

Rene::

You may want to consider using a 4-jaw chuck or getting the Bison 3-jaw chuck to replace the existing Sherline one.

.vp

Thanks Vince. Why?

Rene::

You mentioned that the stock was being pulled away while performing the cutoff operation. This could be due to the reduced gripping capability of the 3-jaw owing to the fact that it is a scroll-type.

.vp

Ah, thanks. I’ve been wondering if it could be also due to a non-perpendicular cutting face on the parting tool.