Once all six parts of each cylinder were soldered together, I really wondered if I would be able to add the yoke too. I wanted it soldered for strength, but feared turning the cylinder assemblies back into their constituent smithereens.

I needn’t have worried. The hard part turned out to be holding the chassis in position while I soldered the yoke to the ends of the crosshead guides. A sodden paper towel and a deft touch took care of the excess heat. Even those pesky oil cups managed to hold tight to their guides.

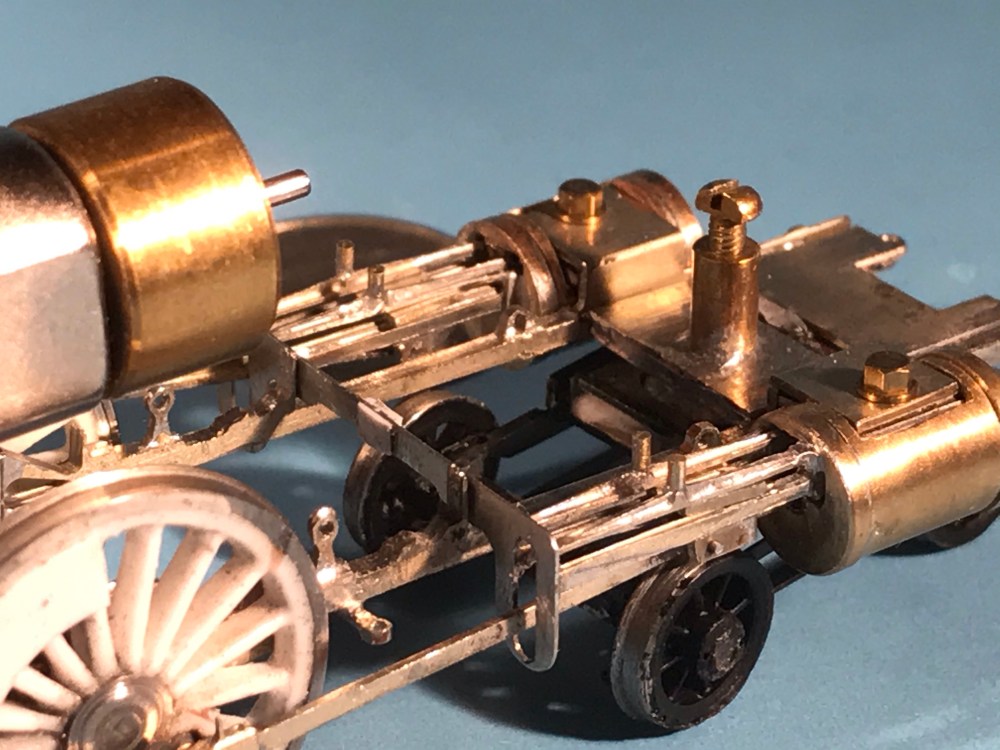

After soldering, the ends of the crosshead guides needed to be made flush with the yoke. To support the increasingly unwieldy assembly, I created a little fixture out of scrap fret. It supports the edges of the yoke, while allowing the guides and main rods to pass through. Clamped to the side of the bench, the fixture made quick work of cleaning up the ends of the guides.

Fixture for holding the yoke for finishing

Filing the ends of the crosshead guides flush.

Of course, the yoke was a solid piece of metal, and it made a dead short across the chassis. So, I glued a piece of styrene to one side, filed a gap, and completed the sandwich on the other side. This thick spot should line up with the spring that assists engineers in lifting the Stephenson’s link and lurks in the murk beneath the boiler. It shouldn’t be noticeable.

Are you using different melt solders? Or just one temp for the whole project?

Craig

I have different temperatures, but so far have not broken out any different ones.

I’m almost finished with soldering, in fact. So the answer might wind up being that I am using all one temperature.