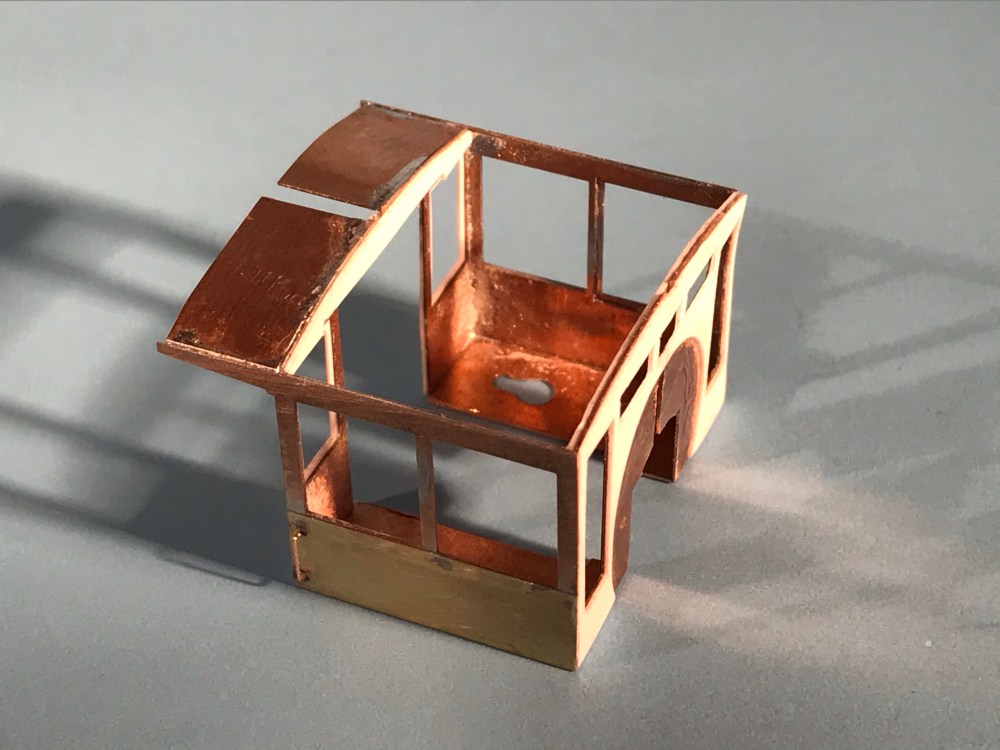

As with every other part of 622, the cab needs to be electrically split down the middle. So, the front and back of the cab are made of two layers – the inner phosphor bronze and the outer styrene.

Before I could add the styrene, I had to correct the cab sides, however. The etching is correct for the cab as built, but by 1905, the cab sides had been covered with sheet metal. I followed the prototype with a layer of .003” brass sheet. This received grab irons at the rear corner of the cab, and all were soldered together.

The Cricut cut the .010″ styrene for the front and back last week when it was also forming parts for the tender tank. The layers fit into recesses made by the outer layer of the cab sides gratifyingly, and a little thin CA grabbed them for good.

Then, I used a needle file to part the cab core roughly in the middle. A second layer of styrene bridging the gap on the inside made the assembly surprisingly stiff.

Could you give your reasons for the split construction? I am sure that it is in earlier posts before I started following. Thanks

I guess there are two reasons:

– I want to maximize the number of wheels picking up electricity. I should be able to easily get six wheels on each side, and maybe eight if I play my cards right on the tender.

– There is little room in this engine for wires, much less wipers. The pilot truck in particular is very lacy; where would I affix wipers, and then how to feed the signal to the decoder? The complications in construction are relatively solvable compared to those of wiring.

Cheers,

Rene

Rene,

Curious as to why you did all that work with the cab rather than use non-conductive materials? Does it have to carry current as well? Seems like a lot of work when it could have been 3D printed or something instead but, as with all things on this project, I’m sure you have a good reason!

Brain

Hi Brian,

You’re right, everything has a reason, although not always a good one! In this case, the walls at the window openings are too thin for 3D printing (at least at Shapeways), and anyway, I didn’t want to chance apparent layers on the cab sides. So, that leaves Cricut, laser or etching. I went with etching for the following reasons:

– I had lots of room on the PB sheet for it, so there was no risk if it didn’t work out.

– Folding it up from the bottom meant I could easily get it square.

– Metal is much more robust than plastic, which is a consideration when you’re assembling and disassembling a model over and over again.

– PB weighs more than plastic, and it is in a crucial location.

In the end, it was a little experimental. I knew I could always go with a full styrene cab if it didn’t work out. However, it did work, and it is better than a full styrene cab.

Cheers,

Rene