One of the supposed benefits of writing and blogging about my projects is that I can go back and repeat a technique that was successful, and sometimes avoid the ones that weren’t. Unfortunately, when it comes to how to roll the plastic sheathing for the boiler, the book on #10 is like a nude by Matisse: missing some key details.

My recollection was that it involved boiling water, elastic bands and a form of approximately the right size. I made #10’s boiler from two layers of .010″ styrene because there was so little clearance around the motor. #622, by contrast, has a luxuriously large boiler, and with the pre-made weight giving the structure for .020″ boiler sheathing, I decided to go with a single layer of .020″ styrene for most of the boiler.

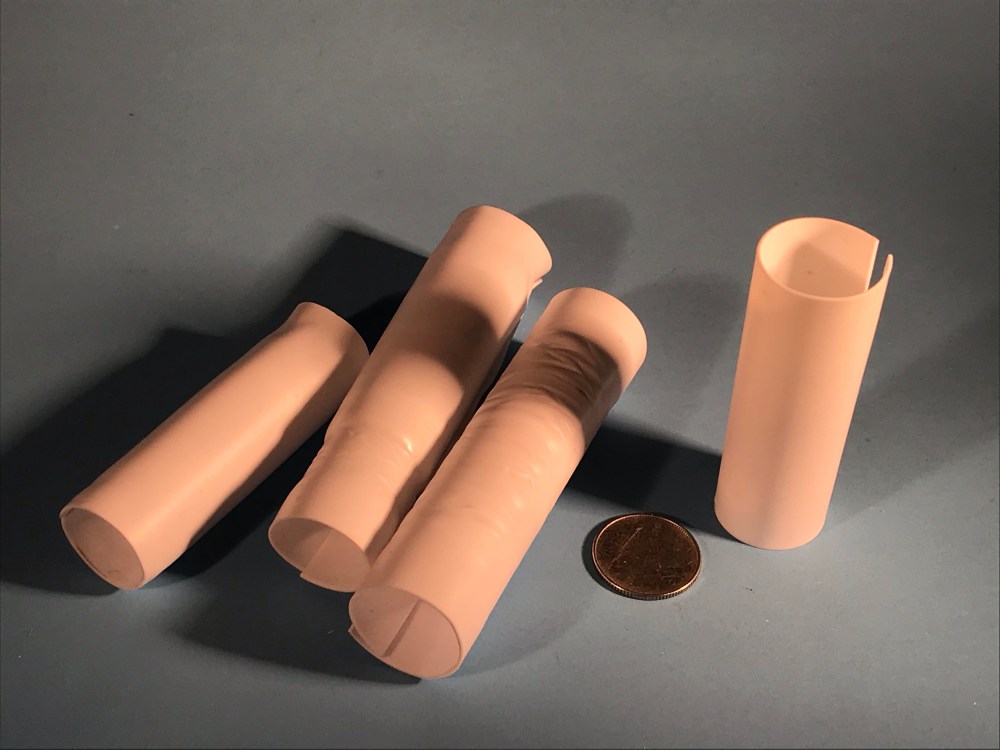

If it took boiling water and elastics to form the thinner plastic for #10 I reasoned, surely more boiling water and elastics would be better for plastic twice as thick. Converting the kitchen to a mad scientist laboratory took only a moment as I set a pot of water to a galloping boil and arrayed my materials. At the end of the evening, I had produced three tubes with all the boiler characteristics of carrots. I decided to call it an evening.

The way to form both .020″ and .010″ (.5 mm and .25mm) styrene into boiler parts is to put the styrene into just-boiled water, and let it cool against the form. This time I used duct tape to hold the plastic against the form, rather than elastics. The difference between the thicker styrene and the thinner stuff is that I couldn’t form the thick stuff until it had been softened in the hot water. Then, while it was pliable, I quickly wrapped it around the marker I was using as a form, and taped it in place. I then refreshed the water from the kettle and dipped it back in. I let the form and plastic sit in the cup until the water was lukewarm, and then dumped the water and let the plastic cool completely before removing the tape.

I made the part a little long and trimmed it to final dimension once formed. With the thicker plastic, in particular, there is a little distortion around the edges, which was easier to remove than to avoid.

…that 20 thou styrene is 16 *times* (2^4) stiffer than 10 thou doesn’t help either. I wonder if laminating 10 thou wouldn’t have been easier? That’s what I did recently with a laser cut Bunker C tank using 10 thou laserboard.

md

Hi Mark, Two layers of laminated .010″ was exactly what I did for #10. The .020″ on 622 feels much more solid, even over the parts where there is no 3D printed steel beneath.

I need to move forward on a steam loco project and this post may push it all forward. Thanks!

Glad to be of service, Eric!