It is better to leave a detail off than to make it too heavy or over-scale.

Typical line fences, such as the one at the edge of the pasture, or the fencing for the cattle pens, are a mesh of wires no more than 1.5 mm in diameter. That’s less than .02 mm in HO scale, or about a third of a human hair. I’ve always felt that modelling such a fence would be at best challenging and at worst chunky. And at 60 cm from the edge of the layout, most of them would be all but invisible anyway.

Then Rob Kirkham showed up at our local modelling night with a spool of stupidly fine stainless steel wire (available on Alibaba or Ebay). At .03 mm, it is finer than typical human hair, and a whole lot stronger. Despite the stuff being 50% overscale, it is almost invisible and so I gave it a whirl.

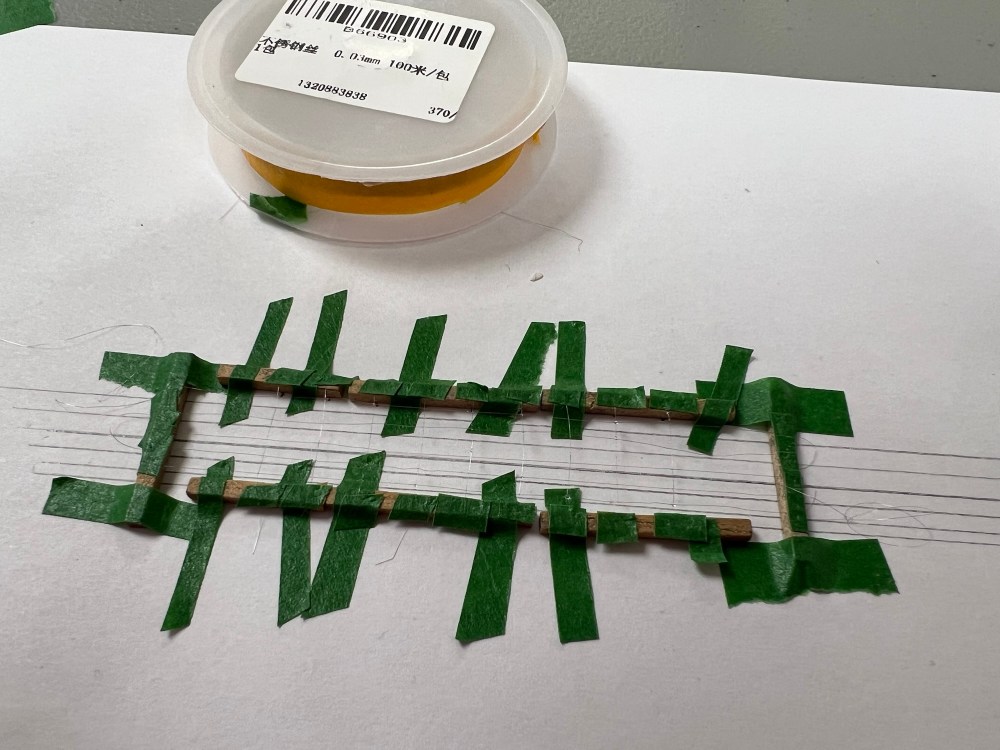

At first I tried taping some longer pieces of wire to a paper template, and knotting the verticals in place. After 20 minutes, I had made exactly one knot, and it wasn’t where it was meant to be. Rob suggested glue, and I rigged up some pieces of wood I had on hand to lift the wires off the surface of the paper. Then I wove uprights through the longer horizontal wires, and held everything in place with tiny squares of tape.

Once I had about a dozen verticals, I waved a pin of my thinnest CA at each of the joints. I couldn’t see what I was doing, so waving was the best I could do. Maybe I hit some joints, or maybe I would be off the hook and able to declare this experiment an abject failure.

I let it sit while I worked on the top rail for the cattle pens, and then came back to it near the end of the evening. Sadly, the method almost works! Once the piece of mesh was removed from the makeshift loom, most of the joints held fast, and enough of them held to demonstrate that the process has promise.

Once posed in the cattle pen fence, the mesh looks almost perfect, especially in the even fluorescent light where the modelling nights take place. Under more directional light, it has a sparkle, which I’ll have to kill before the technique is perfected. Well, thank-you Rob, you’ve dropped me into yet another rabbit hole!

Happy to help Alice, er, Rene. If the Hatter is correct, it’s always 6 o’clock, so this won’t be so time consuming.

I’ve been thinking about how to model this type of fence for years. A jig like you mocked up will help with a square grid and (perhaps with magnification) accurate glue joints. I’m impressed how little mass the thin CA has in the photo you posted.

While there are many ways to approach it, I suggest if the jig and assembled mesh can be moved to the layout and the mesh placed while still in the jig, you reduce the risk that the hours put into the mesh are lost in an unhappy incident.

One idea is to make the fence posts extra height, and mount the tops of the posts into holes drilled into a length of balsa strip wood. Place the wire onto the posts in this set up, and weave/glue the mesh. Take the whole section of fence & balsa strip as a unit, and insert the lower ends of the fence posts into identically spaced holes. Once secured, remove the balsa strip and nip off the tops of the posts about the mesh.

Alternatively, use the balls strip as a base that will be glued into the scenery. Glue the bottom of the fence posts into holes in the balsa strip and build the mesh onto that assembly. Going (router?) a groove along the fence line to accept the balsa strip, and insert the whole assembly. Disguise with paint, dirt and weeds.

Typos, sigh. In the last paragraph, I meant “balsa” not “balls”, and “gouge” not “Going”.

Ah, the modeling challenge of fine wire and cable. See also, trolley wire and catenary, which is a delight to see modeled but is inevitably over scale and prone to unprototypical kinks and the like.

Great work here in any event, will certainly refer back to this for my own modeling in the future.